Position : Home > Product > Leaf Spring Machines > BZS Parabolic Rolling Machine

-

-

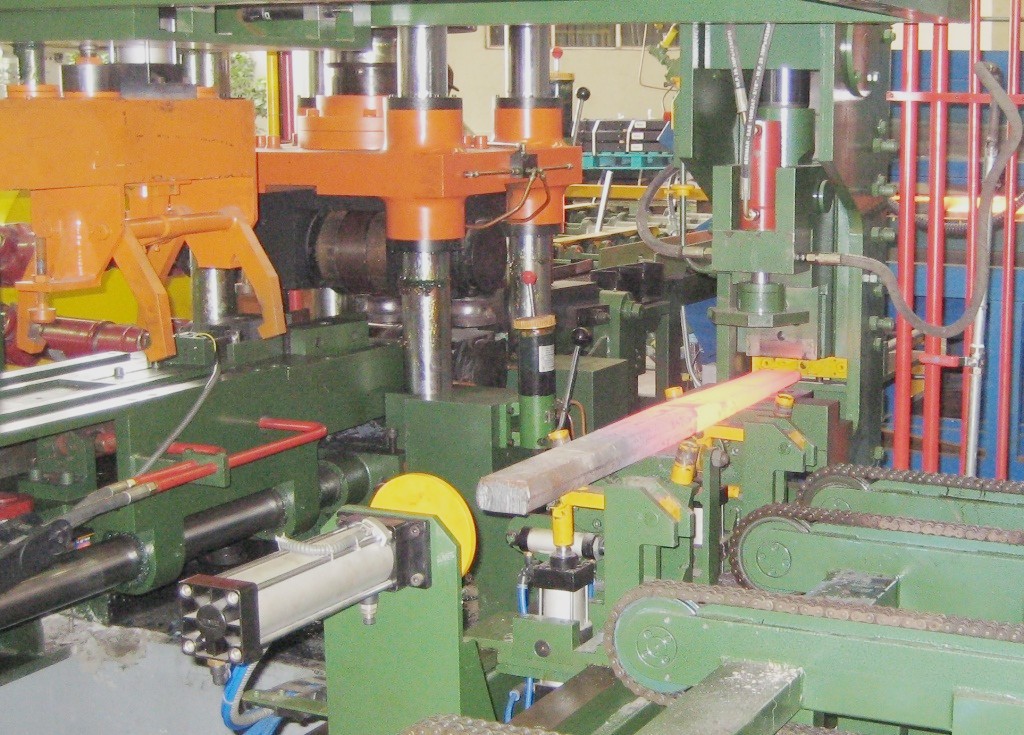

BZS Parabolic Rolling Machine(roller driven by mechanical units)

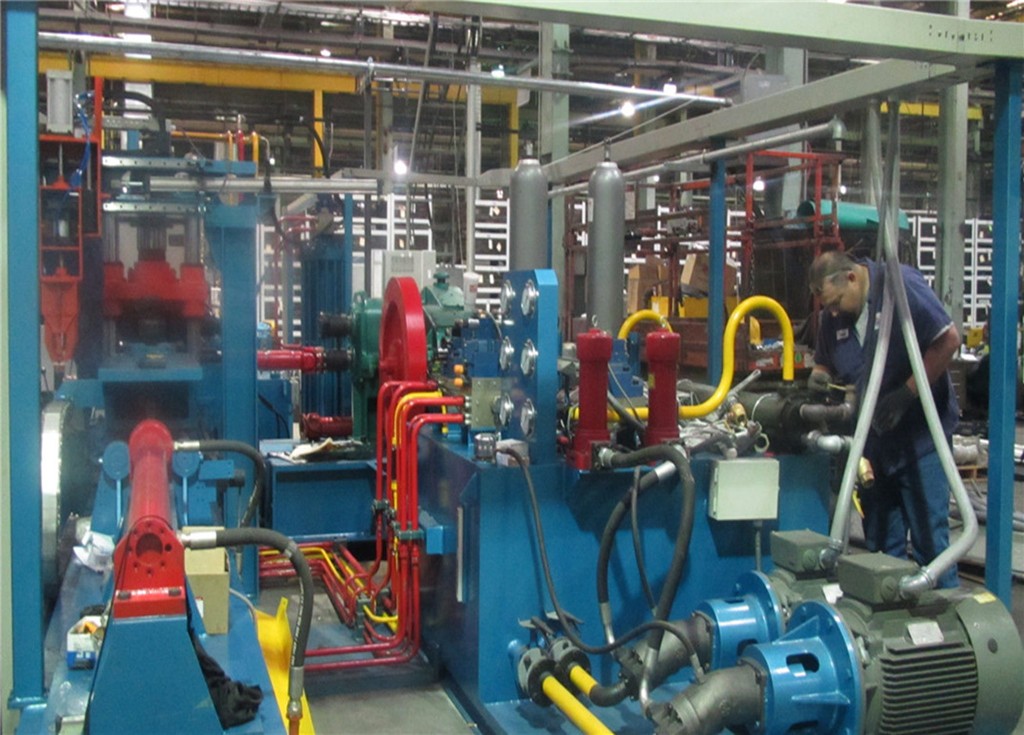

This parabolic rolling machine is specially designed for light and medium leaf spring parabolic roiling as well as some kinds of heavy spring rolling. It has the advantage of lower investment cost, smaller motor capacity for lower working cost, easy to operate and easy to maintenance and etc. The PLC control makes the rolling without any die to roll different types of shapes. All what you do is just to enter a few parameters in the computer.. The Bosch hydraulic ratio servo valve is reliable and has fine anti-pollution functions. To meet different requirement of users, we offer semi Automatic or fully automatic line on option. The basic semi-Automatic line could just has a furnace and a rolling mill. The automatic device could add furnace loader, manipulator after rolling, straightening device, end cutting device, center hole punching device, cooling conveyer, stacking device and so on.

Details

Main parameters for rolling mill.

|

1

|

Horizontal rolling force max

|

980KN

|

|

|

2

|

Vertical rolling force max

|

100KN

|

|

|

3

|

Useful diameter of horizontal rollers

|

∮200-∮180mm

|

|

|

4

|

Useful diameter of vertical rollers

|

∮120-∮100mm

|

|

|

5

|

Speed of horizontal rollers

|

30rpm

|

|

|

6

|

Max thickness of plate

|

60mm

|

|

|

7

|

Min thickness of plate before rolling

|

5mm

|

|

|

8

|

Max width of plate before rolling

|

120mm

|

|

|

9

|

Min width of plate before rolling

|

40mm

|

|

|

10

|

Length of plate before rolling

|

2500-780mm

|

|

|

11

|

Max rolled length of plate

|

1300mm

|

|

|

12

|

Tolerance of rolled thickness

|

<±0.15mm

|

|

|

13

|

Tolerance of rolled width

|

<±0.50mm

|

|

|

14

|

Rolling efficiency

|

2 strokes

|

≤ 35secs/end

|

|

|

|

3strokes

|

≤ 45secs/end

|

|

|

|

4 strokes

|

≤ 55secs/end

|

|

15

|

Motor power of rolling system

|

37kw

|

|

|

16

|

Motor power of hydraulic unit

|

30kw*2

|

|

Heating Furnace for Parabolic Rolling Machine

Next:No Information

Product

Contact

Shandong General Technology Co.,Ltd.(SDGT)

Add:53 Luoyuan street

Jinan, 250011, Shandong,

China

Tel: (86) 531-86020106 / 86022286

Fax: (86) 531- 86028606

Zip Code:250011

Email:sdgt@sdgt.com.cn

Web:www.sdgt.com.cn